The Design

My brilliant cousin Sage suggested that I give some quick details about my project, mostly the fact that it is 196 s.f. so that her co-workers will believe her. It is 196 s.f. 🙂. My house is built on the bed of a 24′ long (8 foot wide) flatbed trailer. It is built on a trailer not as much to be mobile so much as to use a work around from building/zoning square footage requirements. Not that my house is unsafe by any means, I now have to go through the DMV and pay their fees associated (a lot less) to get the house inspected/licensed/permitted. I am using reclaimed/recycled/leftover materials for the most part. I have designed this all myself and have been constructing it with the help of my dad and my boyfriend, in my spare time. Please feel free to shoot me a comment or a message if you have any questions, I am happy to help whomever however I can! Also, if you see me doing something wrong PLEASE tell me, I have a background in design, not building… this is all pretty much from the hip ;-). Thanks! Onto the design:

Right now I am going to be using recycled pallet wood for the siding (shown in the variegated brown). The darker material is just going to be stained wood. The roof and shorter side wall will be an elastomeric roof of sorts with a trellis of sorts for growies (thinking about using expanded aluminum). The deck is yet to be determined.

Lacey, I wonder where you got the idea to use pallet wood? Will it keep the weather out? It must because I am sure that you researched – but what is the technique for application?

Hi there Laura, I just want to avoid confusion down the line and clarify that my name is actually Macy. As far as the pallet wood it is an original idea I had. I have seen it used on interior walls before and I like the way it looks. I am using a rainscreen wall system (http://en.wikipedia.org/wiki/Rainscreen_cladding) on my exterior which allows me to use pretty much whatever facing I’d like. Since pallets fit into my idea of how I want the home to look as well as the budget I was pretty sold!

The pallets act as a first defense against rain but they will not keep everything out. There is a cavity space behind them (in front of the vapor barrier) which allows water that does penetrate to drain naturally and also airflow to evaporate. I figured this was that best system for a movable house as most of the issues with walls are caused by allowing water in (usually accidentally) and it not being able to escape. I have just counted on it coming in and am giving it an avenue to escape. The structure of my house is behind waterproof barriers.

Thank you very much for the question. I have learned about rainscreen walls in theory but this is one of those other things I am testing out here with reality. I will definitely post on the successes and failures in the future!

Sorry about that Macy!

Thank you for the information on rainscreen! I will look it up. I suspect that with my aluminium sheething I may be able to do something like this too. I really look forward to seeing yours on!

THO may very well steal your idea!

Besta, best,

Laura

No worries at all! and yeah, you ought to be able to do something like that though it wouldn’t be as necessary with aluminum, it’s a pretty waterproof material. There is a little more effort and material that goes into a rainscreen but you could do it either way! I love watching your progress!

These are great ideas but what about the weight factor. Weatherproof is not an issue because wood has been used for siding since the beginning of time when man built houses. Laping them and staggering the joints, as siding should be done, allows for water runoff. But weight may be an issue. 🙂 I simply LOVE this idea.

Rebecca

Hi Rebecca, I have a post about determining weight here, http://minimotives.com/2013/02/26/tiny-house-weight-debate/, my siding is not lapped but it is part of a rainscreen wall application which basically allows water to run through, lapping is definitely another way to go! Thank you for your kind words!

Macy, buen día desde Colombia, quisiera saber con más precisión las medidas exactas en los planos, pues esta muy generalizado y estoy muy interesado en hacer varias réplicas de tu casa para un proyecto qué es algo así como un glamping.

Gracias

So glad to see someone building a totally modern tiny house, love the angles and shed roof. I’m enjoying your blog, thanks for sharing your project.

Thank you Cxdyer (I’d use your real name if I knew it, Cheri?) I am going to enjoy yours too!

Yeppers, Cheri Dyer from Houston Texas. (Thats where we live now) but the house we are building is in an hour north of here, in a really small German town.

Yeppers, Cheri Dyer from Houston Texas. Thats where we live now, but the home we are building is on an acre of land in a small German town about and hours drive from here.

hi macy

my name is mim and i am planning my tiny house on wheels….

i came across yours and am interested in some aspects of your design…

i have a couple of questions….does your gooseneck trailer have that large arm to connect to a pick up truck or can it be hitched on to a vehicle like other trailers….and is that the reason for the overhang bedroom?

i too am interested in a foldable deck and am wondering what material would be light enough to fold but strong enough to use as a deck….and what about the support?

i will not build this house by myself…i know my limitations and i would be lost completely….i am good at supervising : )

i am interested in your roof and back wall which you rendered in black….what material would that be….can it be made of one or two pieces piece so there would be no problem with rain….i am trying to understand the different materials that can be used…..i think i would like a metal roof and siding since it would be lighter weight….

i am not sure of so many things and i am not sure where to get all the info…..any info you can give me i would so appreciate….

do you have any pictures of your little house? i dont see them on your website….

thanks

mim

Hi Mim, thanks for the comment and awesome questions!

The trailer does have the large arm to connect to a truck but it is a type of trailer designed to connect to a truck above the rear axle (in the bed of the truck), it cannot be attached to a truck as a standard pull trailer would be for any transporting (we do do this to move it around the property but it is definitely not road worthy like that). This was the type of trailer that was available when I bought it off of Craigslist, it is more the reason for the overhanging bed than the other way around. I started with the trailer and then designed from there. When I originally started I was looking for a standard hitch pull trailer, there weren’t any available in my price-range though so I took the goose-neck direction instead.

I have not worked out all the details for the deck as of yet. I was thinking I would use some expanded aluminum material but I will have to be careful so puppy finger nails won’t get caught in that too. That is going to be one of the last phases of the project so I have been focusing on other parts first but I will certainly continue to updated that as I get closer. The whole system though will be designed for the trailer so the supports will be included with that TBD design as well.

My roof structure has actually changed quite a bit from that picture in material, not shape. I have ended up going with TPO (a plastic membrane) which will have ivy growing up it. You can see the latest images (with the membrane installed) from my latest posts, particularly here, http://minimotives.com/2012/07/29/update-7-29-12/. and also here, http://minimotives.com/#jp-carousel-915. I originally had planned to do the roof and side wall in metal roofing, I just couldn’t come up with a way to do this that I was happy with though, there would either be a weird bend, improperly installed finishes or it wouldn’t look as monolithic as I wanted… this led me to ultimately use TPO roofing which is readily available and used as a standard roofing product in the majority of big box retail centers so it is tried and true, which is important to me. TPO is also lighter weight than metal roofing which was an accidental pro.

Thanks again for all your questions, I love that someone is finding my documentation useful, I am always here to chat about other concepts as well. There are a ton of pictures all over my site starting before the first day of construction. I am guessing you are using a browser not supporting wordpress or on a mobile device that isn’t showing them properly. Each post I have has anywhere from 5-25 images along with it. If you look directly at minimotives.com you will see the posts, or click the orange link (‘minimotives’) to the left. There should be more than enough images to show the entire process and each detail along the way. Let me know if you still continue to have problems viewing the images and I will look further into that, thanks for that intel!

hi macy

its been awhile since i contacted you…..thanks for taking the time to explain it all to me and all the great info….

as of this week i have finally resolved my split from my partner where he bought me out of the house and i am ready to fully concentrate on my tiny house…..yay!!!!!

i have two questions….what do you think of building with sip panels?

looks like it might be lighter and very well insulated….

and the other thing i have been contemplating is framing in steel since the story of the burned down tiny house…and also because steel is lighter than wood………take a look at tinygreencabins.com…..

please let me know what you think?

thanks

mim

Awesome! that is really the biggest part of the process, at least it was for me. Tying up loose ends. I am sorry to hear things didn’t turn out well but happy to hear your positive outlook! I think that SIPs panels AND metal studs are both GREAT ideas. I was initially going to go with SIPs panels for the ease of the system all around. I couldn’t find a sponsor and I couldn’t fit it into my budget otherwise though so I couldn’t make it work. From there the next plan was to do metal studs… then I got a great deal on lumber so I went with the traditional wood stud construction.

A couple things to keep in mind, the steel studs won’t keep your house from being flammable or even offer you more time to save your valuables. The sheathing and insulation in all likelihood is what would bring the house down. SIPs panels however, I have heard, could mitigate some of that concern. The wiring goes in conduit so things would be less likely to arc and start something (like insulation) on fire. It won’t help against a nearby barn burning and taking your house with it but in my opinion SIPs are the best all around option, even though that is not how I built my house.

I am not sure if SIPs are really that much lighter than traditional framing at the end of the day however, they use two pieces of OSB instead of one and because the lack a good portion of the studs these pieces are usually thicker. It’s probably a wash weight wise but they are a much tighter construction method which is important in a small house. Depending on your helpers situation too, it may be more difficult to construct because you’re dealing with 4’x8′ panels which can be heavy and tough to move around without 3-4 people or a tractor. If you do go with metal studs WEAR GLOVES! They will cut you up! But they will spare a lot of weight!

Thanks for the questions, I wish you the best of luck! Are you going to document your build by chance? I would love to follow along!

Best Wishes,

Macy

hi macy

thanks for the positive advice and encouragement….being in transition is interesting and difficult and any encouragement is much appreciated……

i would love to document my build except that i dont plan to build it myself so am not sure people will be interested in reading it…i plan on supervising : ) so that might be an interesting perspective for some….

and i have some unique design ideas…..

i am looking for somebody very good to do it for me……at the moment it seems to me that some people do the structure of the building well and others do the finishing well…so far i have not found one person that can do both really well : )

since i was a designer in my previous life i am very particular about the details……

a question about sip panels….when you say the wiring go in conduits do you mean to say they will be visible on the outside walls? that i cannot live with……so it might be that my options boil down to steel framing…..

please advise

thanks

m

The conduit is inside the wall, not visible from outside :).

yes…i looked at the tiny sip house and saw that it was not visible….

i thought that the panels are ready made and maybe it was not a good idea to open them to run wiring…..but i was mistaken…..

macy i like that you did your house with drywall….i too dont like the tongue and groove wood for the walls….makes it look a bit coffin like : )

but i read today that when towing due to potholes and railroad tracks etc… the sheetrock might crack…..what do you think?

what about ceramic tiles? would that possibly crack in transit as well?

i have emailed several companies that build tiny homes to ask some questions and see which one would be a good fit for me….

do you personally know of anyone that is very good at what they do?

When I started this I was willing to roll with the cracks in the Sheetrock, I feel comfortable patching drywall and I haven’t planned on moving it too terribly much. It seemed like a much smaller issue to me than dealing with a design i didn’t like as well. Since then there are a couple people who have done sheetrock as well AND moved their house with no problems at all, http://clotheslinetinyhomes.com/ for example. They are actually who I would recommend you talk to about a custom design/build as well, they have done a really great job on their place and it seems logical to keep the design/build team together. http://tinyhousemap.com/ is another place to search for other builders to quiz, definitely worth the look if you haven’t seen it yet. I am actually scared more about ceramic tiles, I am using some in my shower, I fear they may pop off and break a bit easier and be a bit more tricky to repair, but I plan on crossing that bridge if/when I get there, I will certainly update as needed! Thank you so much for all your questions!

hi macy

i have looked into clothesline homes….i have two issues there….one they dont build with sips and the other is that some of the finishes in their house is not well done….i was disappointed…..

but when i went to tinyhousemap i found a very interesting site that i think will interest you….maybe youve seen it already….its called boneyard studios…..i was amazed that a young woman bought a small alley lot in washington dc and got zoning approval to put 3 tiny houses

on wheels onto it…..can you believe? they are having an open house on january 6….i hope to attend……check out the site….each of them is building a different style house and i found the blog interesting……one of them is building a 10 or 11 foot wide house which will need a wide load permit every time it is moved….thats an idea to consider as well if the house doesnt get moved a lot…..

there are so many details to think about and i am not committing yet which does not make me too happy……i dont know where i will put the house so that makes me nervous……hopefully i overcome my trepidation soon…..

m

A lot of builders haven’t built with SIPs because they haven’t had the opportunity to, it’s not that they can’t. A good builder works with the client to get them a product they are happy with. I can understand the other concerns though as well.

I have heard of Boneyard Studios, they are pretty new to pop up on the radar but have become very popular (relative to the tiny house community) in a short period of time. They are definitely doing interesting things. The other one to keep your eye on is Jay Shafer in his new endeavor. he is creating a tiny house community. Many people have talked about it but he is having tremendous success in pushing it forward. http://www.fourlightshouses.com/pages/the-napoleon-complex this was very recently released as well.

I hope you can work through your trepidation as needed, that is part of the fun stuff to though :).

Macy, have you heard of hot mud for sheetrock for tiny houses? I’ve seen it – it looks the same as regular – but I don’t personally know anything about it’s stability. Could be worth checking out – it’s supposedly more resistant to cracking. Good luck! I’m building this year too — 112 square feet plus a loft.

BA

I haven’t heard of it in anyone else’s house, I did do a quick Google of it though and it sounds like you have to be much quicker because it sets so fast, I am not sure I have the skills to be that fast. It sounds like it does a good job and would be great for a professional who is generally on a timeline and may not want to wait a day between coats, especially the first coat that takes a lot longer to dry. I think it would be totally worth checking out if you’re comfy with your skills, I think you should try it out and let us know how it goes!

Are you going to document your build? I would LOVE to follow along! Thanks for the comment!

Macy

Hi,

I may have asked you this before but is your trailer 8×24 not including the overhang where the bed is going? What is the measurement of just the lower part where the kitchen, bath and living is? Do you have a diagram? Is the back deck part of the footage?

Thanks

No worries Victoria-

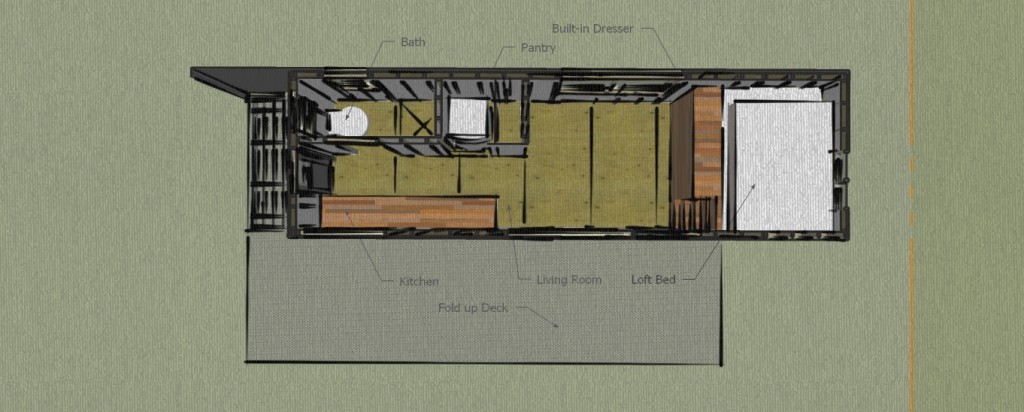

My trailer has a 24′ flat bed, that is not including the 5′ dovetail which I have built up as my porch and also not including the 4′ extension I have built up over the goose-neck portion. Of that 24′ the front 2′ is dedicated to my solar battery storage which leaves 22′ for my living/kitchen/bath area (including the dresser/stair portion). I don’t have a diagram but perhaps I can put one together and post it on this page for reference! Thank you for the idea!

Macy

Macy – I’m going to do a wood tongue and groove interior; I like that look, and I plan to be on the road with my tiny house for a while and think it will travel better.

Yes, I will be documenting my build! I’m blogging (www.aBedOverMyHead.blogspot.com) and I am preparing a website for launch. Happy.

I’ll be following your progress!

BA

That makes sense, I would agree with you about it traveling better. I have listed your blog on my TinyHousers page, I hope that’s ok. I am excited to dig into your site! I will certainly be following your progress as well! 🙂

I love that you listed my blog! I’ll list your site on mine too. : ) Thanks.

Hi Macy! Your welcome to set up house at my place…it’s also a work in progress, but I have two acres with a couple of separate septics and your welcome to plant at the back somewhat wooded area (but….I’m blessed to have trains come through every few hours or so – yes,,I live next to the tracks!) I’m in Tennessee!! Your plans and progress are awesome! Continued luck to you!

Cheri

Haha! Thanks Cheri! I think I might just like living by tracks but Tennessee is too far away from my family! Thanks so much for your comment!

🙂

When you finish, please consider working up a full set of construction blueprints–wiring, plumbing, etc.

Hi Mark! I have been asked enough that I will move it up the priority list, I am going to see if I can’t get the set together before my baby girl is born, if you’d like to please feel free to sign up here, http://eepurl.com/LeAUD, and I will send out an email when they are ready! Thank you for the request, it is what I need to get off my toosh and get on that 🙂

Having helped my wife through her pregnancies with our five children, I believe that when one is pregnant tooshes come in handy exactly for the purpose of resting on them! Thanks for your response, and I look forward to the plans when the opportunity arises.

Hehehe! That would be nice sometimes 🙂 Luckily I can do most of it while sitting on my toosh!

Macy

I found out about your mini home from the NPR article a friend shared on Facebook. I then did some searching and found another article from Yahoo. I have a couple of questions, and I appologize if you have answered it somewhere here on your blog and I am to lazy to read all of them.

1) what type of radient heat do you use? I know Idaho can be cold in the winter.

2) How much insulation did you put in the walls, roof and floor.

3) I understand the composting toilet. What do you do with the greywater from the sinks and shower?

Greg Allshouse

Hi Greg! No worries at all, there is a lot to sift through, I am happy to answer!

1) I use SunTouch WarmWire (http://www.suntouch.com/warmwire/) in my tile floor, I confess that it has not been enough all on it’s own, it works well to about 20 degrees outside for my heat source, we have gotten to -4 though, I had to pull out my supplemental radiant heater which is just an oil based unit from the local hardware store, it was about $30 and does the job well when set at medium when temperatures get too low. (cooling tends to be much more of a hiccup, with lots of insulation the dog/me/electronics tend to add to the heat load pretty well).

2) I have ~R-22 in the walls, R-42 in the floors and R-30 in the ceiling.

3) The grey-water is filtered and collected under the trailer in a 55 gallon drum and used in my garden in the summer and pumped into an overflow drain in the winter.

Thanks for the questions, I hope that is helpful, if you have any others I am happy to help out however I can!

Hello Macy,

I have a trailer support question that you may have come across during the earliest stages of prep-ing the trailer.

Did you have to weld additional “ribs” (the perpendicular metal beams that is used to support the wooden frame) and if so, what metal material did you use? I am having a hard time googling or looking for “cross-brace metal”

Thanks!

Hi Danny! I didn’t but I was specifically looking for a frame that would be good to go, I ended up doing plenty of other work to the trailer I got but the bed frame was very solid! With heavy gauge channels at 2′-0″ on center. I have seen plenty of trailers that would greatly benefit from reinforcing, particularly used RV frames, they are built for much lighter weight structures. I am not a structural engineer by any means but my trailer used 3″ channel steel at 2′-0″ on center, it made it very rigid it also has 3″ channel steel all around the perimeter and tied to each of those ribs. It made it heavy but extremely stiff! Hopefully that makes sense?

Hi Macy, The pallet siding really captured my eye. Wondering what the finish was you used on the pallets? Thank you, Rena

I just bought a planer, planed them down, ripped them to size and put a basic stain and sealer on them, I sort of regret the stain, i think it looked SO much cooler left natural 🙂 You could see all the different kinds of wood!

Hey Macy,

Thanks for the continued answering of my nagging questions.

What degree did you slant the roof and was it enough to just vary the height of the 2 opposing walls? I’m thinking one wall can be (for example) 6′ and the other side 7′ ?

Thanks!

That is exactly what I did, for my material choice (TPO Roof Membrane) I needed at least a 2:12 slope, I built one wall at 7′-4″ and the other at 9′-4″ and it gave me just over a 2:12 slope. I really liked the shed roof because it simplified things in roofing construction!

Hello Macy, I stumbled across your site a couple months back and have found myself returning to it repeatedly for info and inspiration. You’ve made a fantastic tiny home, congrats to you on a beautiful home! I’m in love with the long design you’ve used and I’m planning on doing something similar for my home. (I hope you don’t mind.) I’m in the laying-it-out-with-masking-tape-in-the-living-room stage. 🙂 I’m wondering- how wide is your hallway between the counter and the bathroom? Also, how wide is the door? My door estimate is currently measuring at 22″, which I imagine may be a challenge to find.

Pleased to meet you, and keep up the great work!

Haha, I remember that phase well! FUN! I don’t mind at all, if I can ever hep with anything I am happy to! My hallway is 30″ wide. the door is 24″ and it was hard to find, I would place a 22″ door at impossible! You could always find a 24″ door and trim off 2″ though if it was a solid core door. That particular door is not an exterior door, I couldn’t find one of those but I am surprised that it does as well as it does efficiency wise. Thanks for dropping by a note, nice to meet you too!

I really appreciate your helpful attitude! I’m loving the process of researching every little detail that will go into my new home, and I’m very grateful for resources like your site that allow me to learn from your process!

Hello! I came upon your house while reading other blogs etc. Amazing how much is out there once you start looking. Your house looks very nice and your bog/pics are very helpful. I realize you are in the process of creating plans and do not want to take away from that, but I do have a couple of questions. Were you limited with ceiling height because of the trailer you used, or just a personal preference? In reference to your porch – is that an added piece to the trailer or an original part? And is the side/roof of the porch attached at the end of your house or tied into the framing? Thanks!

Thank you Jim for the kind words! I was limited by the DMV codes for my state, http://towingworld.com/towinglaws.cfm, but I am well under the requirements by my own personal preference. I did have a higher than average trailer bed to start with too but that worked for me because I didn’t want the standard loft. The patio is built over the dovetail that was on my trailer. I had the choice of cutting it off, reinforcing it and building on it or doing less work than either of those and turning it into a patio, I went the patio route :). I’m not sure what you mean by the last question, it is integral to the framing though and the roof of the porch is tied back into the main structure for support to be cantilevered like it is. Hopefully that helps! Again, thank you for the very kind words!

We are needing a little more sqft which is why we need a higher ceiling for the loft. I guess we have to find the right trailer for it. You made good use of the gooseneck which might work for us. Love the patio addition. Lucky you to have that dovetail. Would that be something that could be added on? Wouldn’t want to take away from the length of the trailer. You answered all my questions. Thanks again!

There are some people who add on folding porches and things, i think for transport it would need to be ‘up’ (the license plate and lights would need to be visible at least). It would be kind of tough to have a patio as deep as mine I think without some extra – non-trailer supports. Which is totally doable. The possibilities are really limitless 🙂

Hey Macy,

I just had a quick question for you. I’m just in the middle of designing a garage/workshop for myself and I was intrigued by the pallet wood and rainscreen wall system that you used for the exterior. I was wondering if you could tell me the steps and material you took after the 2×4 framing and osb plywood sheathing, like what came after that in building process.

Thank you,

Franco

I was trying to find you a good detail of a rainscreen condition but Google is letting me down at the moment, here is a guy making one that lets you basically see what’s going on. Basically, after the sheathing you have a moisture barrier of sorts, followed by at least 1/4″ thick furring strips, caulked and fastened to the wall (caulked so you don’t penetrate the moisture barrier), and then the siding of choice can be fastened directly to the furring strips. This wall type accounts for moister flowing through the wall rather than getting caught up. Because of this the siding doesn’t NEED to be lapped unless you want it. You do however NEED a vent at the top of the wall as well as the bottom and it’s a good idea to put a screen on the top and bottom vents so that bugs and rodents don’t get behind there and make messes. Does that answer what you’re looking for?

So the furring strips, they act as your rain screen then, bringing the siding away from the sheathing so no rain would hit the back of the siding material? Also the furring strips you used, there not wood material are they? cause unless I’m getting the concept of the rain screen wrong the moisture and water would get to the during strips causing them to be damaged. also for the vents what material did you use cause the distance along your wall is long so it would be hard to find a material that went continuously along the whole wall.

Yeah it answers my previous questions, I understand the rain screen system more now, thank you and thank you for taking time out of your day to reply to my post.

The actual ‘rain screen’ is the moisture barrier, it is what keep the structure from getting wet. The furring IS what keeps the siding away from the structural portion of the wall though allowing water infiltration and exit between your structure and finish material. Everything outside of the water barrier in a rain screen wall is exposed to moisture but the point of it is that moisture does not SIT stagnant on the materials, it is allowed to get wet and then dry out completely. Rain screens came about because a lot of people would use lap siding incorrectly (in an effort to keep water out) but instead of being able to completely seal the building they ended up having leaks and actually trapping the moisture up against the building, causing rot and mold. The solution was to build a wall system out of the same materials (wood is commonly used in lots of areas) which allowed water to enter and more importantly LEAVE the system. Wood does ok until you submerse it for long periods of time. In really rainy areas they do however use metal furring strips for this reason, if the wood is not allowed enough time to fully dry it will rot over a shorter period of time. We do ok here in that respect though, by nature wood is not as long lasting of an exterior building material but it is fairly common for rain-screen walls to have wood furring. For the vents I just used standard fascia vents, it’s similar to just a screen door but comes in long 6″-10″ wide rolls, it works perfectly! Hopefully that clears some stuff up. If you were concerned you could also use treated wood furring strips. The most important part of that is that they are water sealed when you fasten them against the water barrier. Punching holes via furring strips every 16-24″ o.c. in your moisture barrier would be bad news bears and would make for a very poor rain screen.

Oh ok, now I fully understand the rain screen system. Thank you for clearing that up for me. Another question is what did you use for your moisture barrier?

And how did you water seal the furring strips when when fastened them onto the moisture barrier?

Again thank you so much for clearing this up for me and replying to my posts.

Great questions, my moisture barrier is actually a three in one product which acts as an air barrier, a water barrier and a radiant barrier, I can’t exactly remember the brand (if you searched my site for ‘radiant barrier’ you could find out all about it), it is a perforated foil-like product designed to be these things, it’s similar to EcoFoil’s products (you may say why perforated, that doesn’t make sense for an air/water barrier, it is required in my region though, the building wraps have rating for air transmittance, you can’t have a complete seal or you will trap moisture, in MOST climates the building wrap needs to have a certain amount of breath-ability which is why it’s perforated). Tyvek is another example of a water barrier though which has a breath-ability rating because of how the fibers go together rather than perforation… As for sealing the furring, the back side of every piece is caulked so that there is essentially a plastic gasket around every nail hole that stops water from getting to the hole. It was a time consuming process but a critical part of it! 🙂

Hi Macy:

I have a couple more questions for you. What make of trailer did you use? What are the dimensions of it? I’m really not very knowledgeable about this stuff so please bear with me. Did you have to do anything special with the dovetail to ensure that it stayed in place? You mentioned that you got it on Craigslist. Do you mind me asking how much it cost you? You mentioned that your composting toilet has a heater and a fan so is it safe to assume that you kept the electrical unit? What are you using to cool your home in the summer? Thanks so much for your help/input.

HI Lori-

Absolutely, great questions, the trailer is not a ‘make’, it a home-made farm trailer, it is included in the budget here, http://minimotives.com/budget/ for $500, it needed a lot of work and so I got a very good deal. It is a 24′ flat bed, meaning the flat part is 24′ long, the gooseneck is an additional 7ish feet and the dove tail is 5 feet more. It is 8′-0″ wide. my flatbed is completely above the wheels which allows no wheel-wells (that was nice) but it limited my head height. This worked for me as I didn’t want a loft but it is something to consider when shopping around. The dove tail is permanently attached to the trailer (it is a part of a lot of higher bed trailers and acts as a portion of a ramp in order to load equipment, it is very solidly attached, just not as balanced as the rest of the trailer as it is meant to be used in loading, not hauling. I had to keep any major weight off of it unless I used it in the calculations while re-positioning the axles, which I didn’t. I did keep the electric composting unit, reluctantly, I think the pros and cons are a wash. When I go off grid I will convert it to be a non-electric unit… I have passive cooling for most of the summer (a ceiling fan and open windows at night then seal it up tight so the cool air stays inside), that worked 85% of the time. I used a small air conditioning window for the few weeks we were over 105 degrees. That turned out to be a life saver, I think this summer I will get a swamp cooler and use that. Hopefully I hit everything, great questions! 🙂

So the furring strips you used, what was the dimension of them, like the thickness and width of them. And you just used screws or nails to attach them to the sheathing? And for the pallet wood siding how did you attach those to the furring strips? did you nail them or screw them or use a brad nailer?

Again thank you for taking time to answer my questions

The furring strips are just 2×4’s ripped down to 1/4″ thick so they are 1.5″x .25″. I used galvanized finish nails to attach them, you could definitely use screws. I ended up attaching the siding via non-galvanized finish nails, I would suggest using galvanized unless you like the runny black look you can sometimes get with non galvanized fasteners that get wet. I came to terms with that look :). I would suggest a little bit more than a brad nailer, screws would definitely work there as well but that is a little overkill too (unless you’re traveling a lot with your house, then it may be worth the peace of mind that your siding isn’t going to fly off under those wind loads). Absolutely, happy to help however I can!

hey i left my email an number on info. can you text or email. i really need info and sinces you design can you do models of how i would want my house to look like if i emailed you the floor plans. this is something i have been wanting since i cant afford any thing else. and any ideas would be helping. low on budget. trying to support me an my gf with 5 cats. so yeah .please help if you can.

Hi Jeff, my guess is that it is not cost effective to hire me to model anything for you, I bill out at 100.00 and hour right now and am swamped. Sketchup is free software though that you can download and model yourself? Hopefully that helps!

Macy, love your work. Love it. I’m interested in building a tiny home, and your floor plan is very interesting. There are some ‘sustainable’ buildings in the Portland, Oregon north MLK area which use galv metal as siding, which has this beyond ‘post-industrial’ look. I was thinking T111 for exterior and interior walls for sheer as well as weight. Can dress it as required with 3-8″ trim. Curious about your costs beyond basic materials (2/4″s, windows, insulation, etc.) Seems possible, in my world at least, to do this for under $5K… but that’s with compromise regarding ‘vision’. What do you think? Del Lucas

5k may e a stretch, I think you could get there for around 7k depending on furnishings… My costs, http://minimotives.com/budget/, include all of my appliances and everything. I did a little post about where I could cut some costs, http://minimotives.com/2013/04/16/i-have-exciting-news-about-my-budget/, there are of couse other ways too but those are some of the big ticket items! I would love to see what you do come up with!

hello Macy

congratulations for your house ! wonderful !

i really like your lights !!! could you let me know where you get them ?

many thanks

Hi Isabelle! I made them!! I took a glass blowing class with my brothers, we each made a pendant to give my house some whimsy! 🙂

Hi Macy, I have recently discovered the Tiny House movement and it is something my SO and I have decided we want to do. I was just wondering if you could give me some advice on where to get started. We are wanting to build it ourselves and we both have no experience with construction and I have minimal experience with design. My head is beginning to swim with all this information so I guess I am just looking for a little direction and advice. Thanks for any help!!

Welcome down the wormhole that is tiny house land! It’s addicting! There are some great books I recommend here, http://minimotives.com/resources/. They all pertain to different things sort of, whether you’re looking for actual construction process information or real life accounts of people in tiny houses. I’ve got this post here, http://minimotives.com/2014/09/15/where-do-i-even-start-with-a-tiny-house/. I hear you on there being a lot of info out there, its daunting to say the least. The most important part to remember is that every little step can be broken down into smaller more manageable pieces, and every little step forward is progress! Hopefully some of that is helpful, I would also invite you to join this group on facebook if you’re on there, https://www.facebook.com/groups/tinyhousepeople/, I moderate the group and do my best to keep it a kind, supportive and encouraging place to talk through any tiny house questions with others that are at various stages of the same journey!

Thank you so much! I don’t have a Facebook anymore but my husband does so I will direct him that way. I am super excited and equally nervous to start this journey but so far I’ve been met with nothing but support. Especially from my Mom, which is super encouraging. I’ll definitely be using your resources and your site throughout the process.Again, thank you so much!

Hi Macy,

I’m in the process of designing right now and—gulp— saving up to hopefully begin my build in the next year. I’ve been looking around for the fixtures and appliances and things i will include and i have to ask about your stove. It looks like it is a compact model that, maybe–just maybe, has a moving vent/vents beneath the house? I would love any information you can give me about it. I’m huge on cooking and know i need a range in my tiny, but trying to find something that meets my needs without taking up massive amounts of space (including a range hood above) is difficult. Thanks so much, and thank you for your wonderful site. I have learned so much from you already, and you are definitely one of the people making it possible for me to go tiny!! –Hannah

Hannah! Thank you so much for the very kind words! My stove is a reclaimed one out of an RV that ‘vented’ through an 8″x5″ hole in the wall above it. I did find separate vents that I could use for it that vented below but I instead opted to have an operable window behind it, operating under the assumption that that was better than having a hole in my wall 24/7. I do generally crack a door (even in winter) when I cook and I have a carbon monoxide detector as well as a propane detector but alas it isn’t as fancy as you’d hoped! Hopefully that helps!

What you have achieved is beyond mere description. Both superlatives and language are lacking.

Where I currently reside, the maximum allowable “roadwidth” is 6’6″ , roughly 2.2 metres.

Would you therefore recommend increasing the length , or increasing the height (maximum permitted 2.3 meters, ie: 8ft) in order to adapt your design to local (NZ) requirements?

Watching with very much interest,

Kind and Respectful Regards, Uyraell,

NZ .

OUch! Those are some tough restrictions!! Width is the hard number, the design would have to change completely to be 2.5′ skinnier. I’m not sure it could be made up by going longer… The best starting point is to define what you want in your tiny home, make some scale cut-outs and arrange them in a scale space the size of your trailer. I didn’t realize the restrictions were so rough in NZ! (I was on a radio show in NZ recently! FUN!)

hi! i really want to know what are the measures of this house, how you share out averything

Hi I have plans available here, which detail out every little dimension but the general dimensions are 8.5′ wide by 24′ long, that does not include the patio, which is 5 additional feet. Hope that helps!

Hi Macy, I followed the work of Jay Shafer for years and recently spent more time studying the movement in Portland, Oregon. Now, I am ecstatic to find you where I actually live. So far I have attended one of your free workshops and read as much of your posted information as possible (still more to explore); even sent a couple of “chatty” emails — sorry about that. I have two basic but important general questions as I slog my way through trailer size questions:

1) By what measurement do finished 2’x4′ and 2’x6’exterior walls subtract from indoor floor space? (essentially, finished thickness — guesstimate works) By finished I mean framed, exterior sheath, and indoor sheetrock — a basic wall. I thought this measurement plus my desired indoor footprint would be a good place to start serious trailer planning — even if I end up in the dreaded “wide-load” area. Right now, I’m using blue painter’s tape in my 748 square foot house to find my comfort zone and I have already downsized enough to fit into a tiny house. Is it just me or have modern appliances also grown along with the size of McMansions?

2) What are the pros and cons of 2’x4′ vs. 2’x6′ external wall framing? I’m wondering if 2’x6′ framing might offer some structural pluses to mitigate increased costs.

Thank you, Macy, for all of the information you share so selflessly with those of us who are new to idea that we truly can realize our dreams if we just put in the work and pay as we go.

No need to be sorry at all,, I am just slow! I usually have a day a week I set aside to respond to emails and comments and with the workshops that has been hectic! I am sorry for being slow and like I said before, thank you for coming! (and being so dang nice!)

1)A finished out 2×4 wall is approximately 6″ deep finished, depending on what you choose to finish it with… 2×4 is actually 3.5″ thick, then usually about 5/8″-3/4″ finish on the inside, and 1.5-1.75″ sheathing and exterior finish (include trim depth around openings). A 2×6 wall is about 8″ finished, the only difference being the additional 2″ in stud depth. Since you have two walls you would subtract 1′-0″ or 1′-4″ respectively, Giving you an interior space of about 7’6″-7’2″ on the inside of a tiny house that is 8′-6″ wide (max universally permitted.)

It is definitely not just you, appliances are HUGE too, there are actually some companies now specializing in smaller appliances, you can searc ‘apartment size’ [whatever you are looking for], I know GE has a compact line, they are spendy but its GE (good quality). There is also ‘compact appliance’ and online retailer trying to focus on tiny houses specifically. 🙂

2)I will chat a bit about this this Wednesday, essentially the major benefit in a structure as small as a tiny house is more room for insulation. It’s a pretty important deal IF you live where it gets COLD, cold! I will chat about advanced framing that allows you to use less lumber (but bigger 2×6’s) in a standard application but with tiny houses you can used 2x4s as well. SOOO, unless you NEED super insulation I would count on 2×4’s :).

Hope that helps! See you Wednesday!!

Thank you, Macy, for this great information. Sooo much to consider, it sometimes makes me a little dizzy(er). Really looking forward to all of your workshops — see you at the next one.

The choices are overwhelming, at a point you just have to pick and deal with the cons, each option is workable! 🙂

Hi Macy,

So, I’m thinking about building a tiny house in my spare time as a project (and it will give me a place to live in the future) but I have no idea how to go about designing it. My dad designed and built our family house, but he used a basic design out of a kit for our house. So building shouldn’t be super difficult, but I’m a bit overwhelmed about where to start whit this tiny house. If you could give me some advice that would be great. Thanks! 🙂

Oh boy! That’s a big question! 🙂 I started a website called PlanningTiny.com just to try to help out with this and some of the technical stuff, I am right in the middle of some classes I am giving and recording on this exact subject, once I get them ready in a couple more weeks I will be uploading them to there! There are a couple posts that may help you to get started, http://www.planningtiny.com/browse-by-topic/ Making a priority list and using some cut-outs/scaled items is a good start.

Hi Macy. The tiny house movement just fascinates me, and Of all the designs Iv’s seen yours is my favorite .I’ll probably never live in a tiny house ,but it still is very interesting.Love the videos of Denve r.I’ve had two Great Danes ,and just LOVE them .We used to call them our $10.00 hprses.

Thank you so much for the kind words!! 🙂

Hi,

My name is Jose Manuel, I am 14 years old, and I would like to build one of this in my parents house backyard, to be kind of like my bedroom, with kitchen and bathroom, but I do not know where to start. Could you please give me some advice?

Thank you so much

I would really appreciated.

Jose Manuel

Hi Jose-

Start by figuring out at least ten things you MUST have, like in my case I wanted a great dane to be able to live comfortably, no built ins, an oven, a big shower. Once you have at least ten things get some graph paper and start designing! I have some paper cut outs here, for free https://gumroad.com/planningtiny that you can use to cut out and rearrange until you find a plan you like, then think vertically, where do you want windows and doors, then go to town building! You can collect all kinds of materials as you go! Hope that helps!

Hey Macy, I’m sure you’re sick of answering questions by now, but could you answer a few more? I am designing a tiny house myself, and I have a few questions.

Do you like the composting toilet? If you could redo it, would you put in plumbing?

What toilet did you use?

Is the bed custom-made? If not, where did you buy it?

What is your opinion on shipping containers? I’ve done a fair amount of research on using them as homes and the internet seems fairly evenly divided 😛

Do you often entertain at your home, or just go out to dinner? I am a hostess at heart and am wondering how I could design my tiny house to accomodate people.

Thanks so much for taking the time to read this – I love your home!!

Sabrina 🙂

Never sick of questions, just super slow sometimes! (sorry!)

I LOVE my potty, no joke, I much prefer it to flush systems, I would definitely do it again (it’s a Sun-Mar but they are all pretty similar in how they function)

The bed is just a mattress, the one I had before building my tiny. I made a squatty frame for it so it didn’t get mold sitting on the floor. Nothing special about it though, besides being super comfy!

I love hipping container homes, it is split but I plan on building one some day… they aren’t hugely money saving as I undersstand, and as a ot of folks expect, but they are sustainable, functional, could be stylish etc. Im in the pro container house camp personally…

I definitely COULD entertain, and have had people over but James and I are both from big families, that largely live local and with siblings and parents who trump us on hosting… so we don’t host others often at the house… but I feel we could easily handle some guests, especially with our new patio!

Hopefully some of that is worth something, again, sorry I am terribly slow to reply!

Hi Macy. I love your beautiful space and excited that it incorporates sweet little munchkins (your kids). We are looking at taking a gradual pace to the finale of our tiny house. We need to create an extra ‘bedroom’ in our backyard (thinking 8 x 12′-14′ space). There is no way to create something we can “roll out” once completed (no room). That being said. . . . my thought was to create a space (like an outdoor shed) that could easily be disassembled, put on a trailer, and expanded at a later time. I would love and appreciate any thoughts you could send me. If we take a shed design, we are looking at close to $3000. Money that seems would be better spent with the moving/expansion in mind.

Thank you Macy. Your such an inspiration.

Kelly

First thank you for the kind words, second that is TOTALLY possible, in fact the building industry sort of goes that way sometimes, making preassembled walls then shipping them to the site to be fitted together. I see no reason you can’t do the same thing!

Is it entirely flatbed or are the last few feet dovetail?

Nevermind. I believe I found the specs of your tiny home on another page. 25ft gooseneck w/ a 5 ft dovetail. I see you’ve built a deck on the dovetail. Could this space be enclosed and support part of the interior if you had chosen not to do a deck. The reason I ask is I am deciding on an 18ft trailer with a 4ft dovetail. I’d like to build the floor out with framing like yours but include the space in the interior. I can’t find much on it and am curious to know will this work? Thanks in advance.

Close, 24′ with a 5′ dovetail. The patio was enclosed in 2015 to become a bedroom for my kids, so yes! Dovetails are structural.

Looking at the tiny house, post renovations, would a loft sleeping area work across the width of the back where the bunks are? (Instead of the bunks) I have two teenage boys and don”t think that bunk area would fit them!

Hi April! Yes actually I designed it so that I could move the door and put a twin bunk in there if we still like there when the kids are older. I’d move the door to the same side as the kitchen and have the buns along the back wall